The Technology

The Results

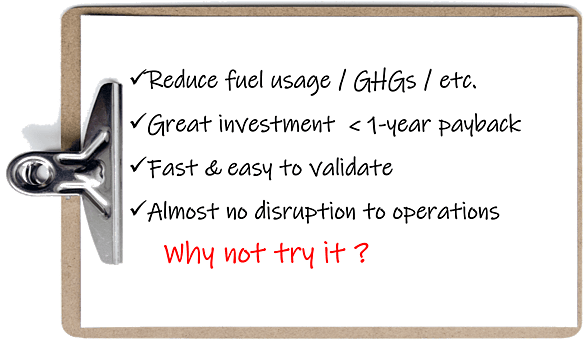

Independent labs and customer-run tests have shown fuel savings from 3% to as high as 12%. We see an average of 3% to 7% for most applications. We have many test results we can share with you. Results may vary based on the application, type of engine, and the type of fuel used.

Results vary because it's super complex, but we've seen soot and PM lowered >50%, NOx, CO & CO2 lowered >40%, VOCs lowered >60%. We have many independent test results we can share with you. Go see the Emissions page. Results may vary based on the application, type of engine, and the type of fuel used.

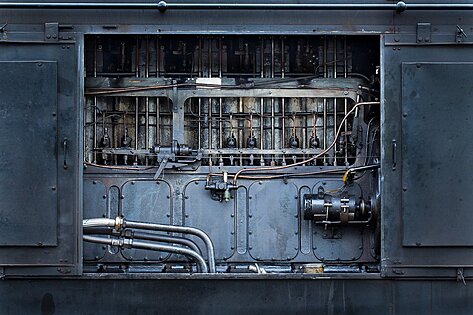

This is a major cost saver of producing less PM or soot in the combustion process. The soot acts as tiny charcoal briquettes that wear away your engine parts like piston rings, cylinder liners, etc. We don't promise a number, but we've had customers go 50% longer between engine overhauls (top end and full).

This is one of several hidden benefits of reducing Particulate Matter (soot or black smoke) and VOCs in the combustion of the fuel. If you're making less soot and VOCs to get into the oil, it will last longer between changes. Results will vary but we recommend changing oil by analysis, not by miles or hours.

Less soot means longer time between required DPF regenerations. Regenerations cost fuel, and the fewer you do, the less fuel you waste doing it.

We have the only technology we know of that reduces emissions while saving fuel. Most methods of lowering emissions increase fuel usage but if you alter the fuel before you burn it, it burns more efficiently - meaning less fuel wasted and lower emissions from the combustion. It's a very different way to tackle the problem and get the double benefits.

Some of Our Customers

"We have successfully piloted the fuel catalyst model HBEN 2012 on our Cat 785C haul trucks with results that surpassed our objectives for fuel efficiency with a payback of less than a year. As a result, we have purchased the fuel catalyst for installation on our fleet. We are also pleased with the trouble-free performance of the catalysts to date. We are looking forward to our continued use of the fuel catalysts."

"When we tested the catalyst on a Cat 785C haul truck, we saved 4% fuel and over $28,550 per year."

One large study reports...

One large study reports...

"…conducted a large test using 42 class 8 trucks where 10 were fitted with the catalysts to compare with the 32 control trucks. The test was run over the entire lifecycle of the trucks covering over 12 million miles. There was an average 4.4% improvement in fuel consumption on the 10 tractors with the catalysts installed…"

"We used an EPA recognized fuel test procedure on 10 class 8 trucks for 95 days and 290,000 miles. We obtained a fuel savings of 4.59% and a very fast ROI."

"We tested on 5 trucks over 66 days and 124,000 miles and reduced the fuel consumption by 5.1%."

Why Zelkam?

We have become a leader in applying this technology to the diesel equipment industry. Brian Livingston, our president, is an experienced Chemical Engineer that spent almost 20 years in Caterpillar's Diesel Engine Division. He combines his decades of experience with Rentar's 20-year history to provide expert advice and guidance on this unique technology. We have saved customers millions of liters of diesel and many thousands of tons of CO2. Reach out and have an honest conversation with him about it and what it could mean for your operations.

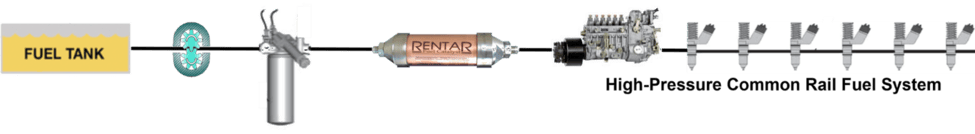

As fuel passes over the rare-earth metals in the device, it catalyzes some reactions in the fuel that increase its ability to burn more efficiently. The catalysts mainly do two things to improve the fuel for better combustion:

- "Crack" longer chain hydrocarbons into shorter chains that burn easier and cleaner

- Take straight-chain hydrocarbons and turn them into ring compounds that generate free hydrogen, allowing the mixture to burn more efficiently.

Both of these allow for a faster and cleaner burn in the combustion chamber, increasing the efficiency. It's not magic or magnets, just chemistry and physics. We have a section on "How It Works" where we go as deep into the science of it as you want to go! Understanding the chemistry and physics of this technology really helped us become believers in it. If you slept through chemistry class, that's OK, we've got you covered!

It mounts in the fuel line, just before the injection pump. Detailed instructions are on the Installation page.

Many customers are skeptical at first. We can relate. We offer great test & validation support.

We have helped many, many customers in all types of equipment fleets test these catalysts. It's done with almost NO disruption to your operations in as little as 250 hours of normal operation. We help you design the test to get statistically valid data to base your investment decision on. Contact us and let's talk about that.

Let's talk emissions

If emissions are your biggest concern, this technology can reduce emissions at a lower cost than any other technology we know of - and it will quickly pay for itself in fuel savings.

There's Something for Everybody

Maintenance

Environment

Immediate reduction of CO2 GHGs

Lower CO, VOCs, NOx, PM, etc.

Less soot = fewer DPF regenerations

Sell carbon credits

Oh, yah - plenty of those.

Sure. Several options:

The low-touch approach.

The medium-touch approach.

The high-touch approach. We're old-fashioned and like this one the best. We like talking to people!

We send out the occasional newsletter every several months. Let's stay connected.

Take the next step - reach out...

If you use a lot of diesel, we can help you use less.

If you make a lot of emissions, we can help you make less.

If you depend on a diesel engine, we can make it last longer.

It's worth a phone call!

I'm Not Ready Yet - But Keep Me Informed

We send out the occasional newsletter every several months. Let's stay connected.

Calculate Your Savings

We can help you reduce your CO2 emissions by 4% - 10%. And it will pay for itself too.

Quickly.