Installation

Installation is quite easy. Any reasonably qualified mechanic can do it in about 30 minutes. Below are specific instructions, pictures and videos to help you understand how to do it. We encourage you to print this page and give to the installer or forward this page link to them.

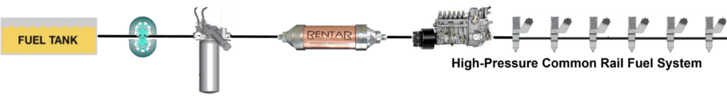

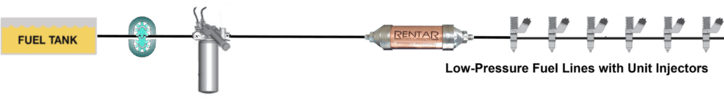

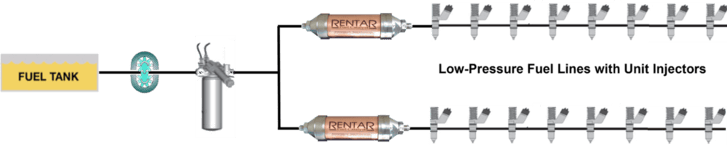

Here are 4 examples

For high-pressure common-rail fuel systems

For low-pressure systems with "unit injectors"

For high-pressure common-rail systems on V blocks

For low-pressure fuel systems on V blocks

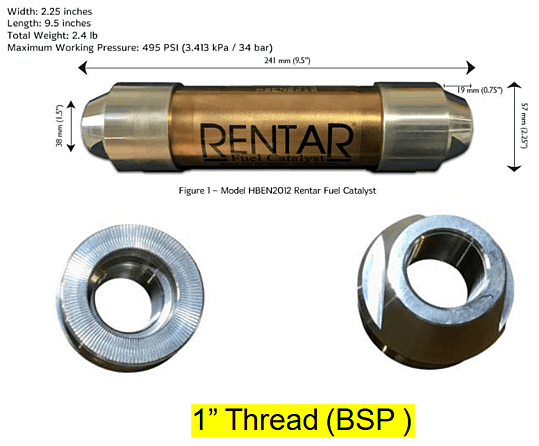

INSTALLATION INSTRUCTIONS1. Remove plastic wrap.

2. Install British Standard fittings to both sides of catalyst and torque to 55 lb-ft or 75 NM.

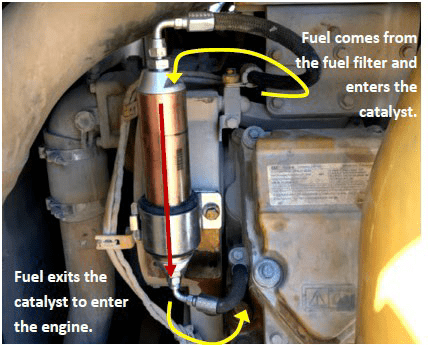

3. Disconnect fuel line from where fuel enters engine.

4. Reconnect catalyst to engine with a short length of hose. (As short as possible: 6" or 15 cm recommended)

5. Reconnect a hose from the fuel filter to catalyst. Any length hose is ok.

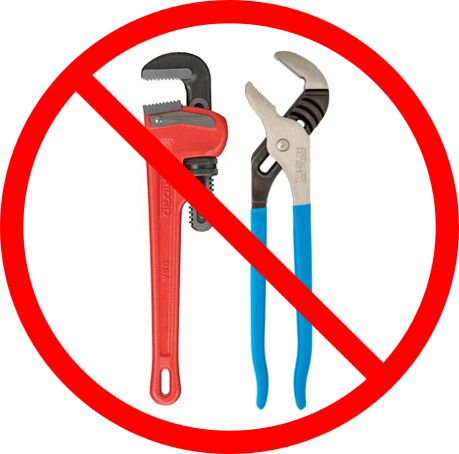

NOTES:a. Do not put tool on copper tube. (Leave the Channellocks in the tool box! #1 cause of damage)

b. Do not bend hose more than 30 degrees. Use a 90-degree or 45-degree fitting when appropriate.

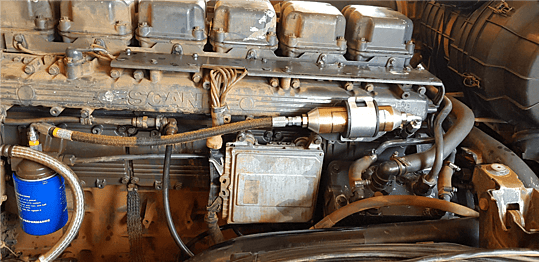

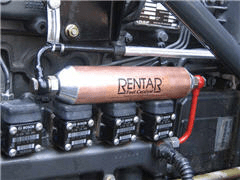

d. Secure catalyst to engine. Usually with a rubberized clamp as pictured to minimize vibration.

e. Catalyst is Bi-directional - it can be installed either way.

f. If installed vertically, flow fuel from top to bottom.

Send us a picture to confirm proper installation!

Video of Installation on a Cat D9

Proper Installation of Fittings

This video shows the proper way to install fittings without damaging the catalyst. He shows how NOT to do it as well. Watching this will prevent the #1 cause of damage to these catalysts.

Proper Use of a Connecting Hose

We always want to install the catalyst as close as possible to the point of combustion - usually at the inlet to the fuel pump.